LCD refers to the liquid crystal display screen. It is a type of flat panel display and is used for screen displays on televisions and computers. The LCD screen uses a liquid crystal solution in two polarized materials. Passing an electric current through the liquid rearranges the crystals to create the image.

he structure of the LCD screen is roughly as follows: backlight layer – first polarizer – TFT film substrate – liquid crystal layer – TFT film substrate – C/F glass (color filter) – second polarizer.

The light-emitting principle of the LCD screen mainly relies on the backlight layer, which is composed of a large number of LED lights. When the light emitted passes through the first polarizer and the liquid crystal layer and reaches the second polarizer, white light can be seen.

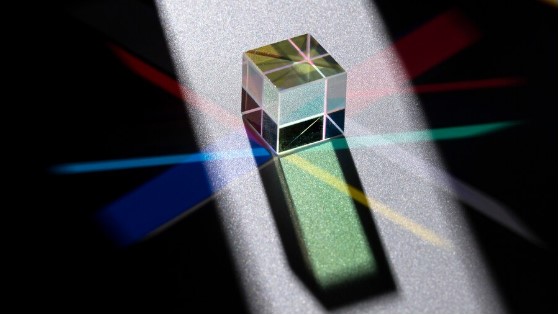

But white light cannot display images, what should I do? So a colored film, a color filter, is added between the liquid crystal layer and the second polarizer. White light can display red, green and blue through the film.

The TFT film substrate controls the intensity of red, green, and blue light.

Classification of LCD liquid crystal displays

LCDs made using the photoelectric effect are roughly divided into the following types: TN-LCD, STN-LCD, HTN-LCD, FSTN-LCD, and TFT-LCD.

TN-LCD is a twisted nematic LCD. Most of the LCDs we usually see in electronic watches, calculators, game consoles, etc. are TN-LCDs.

STN-LCD is the abbreviation of Super Twist Liquid Crystal Display. That is, super twisted nematic LCD. It has a similar structure to TN-LCD. The difference is that its twist angle is not 90 degrees, but between 180 and 270 degrees. Although the twist angle is only different, its working principle is the same as TN -LCD is completely different.

STN-LCD is the mid-range product currently produced by LCD. It has the characteristics of displaying a larger amount of information than TN-LCD. It is mainly used in a variety of instruments, Chinese display machines, notepads, notebook computers, etc. The manufacturing process of STN-LCD is basically mature, but the main technology is in the hands of a few countries such as Japan and South Korea. There are more than ten STN-LCD manufacturing companies in China.

HTN-LCD is the abbreviation of Hight Twist Nematic Liquid Crystal Display. That is, a highly twisted nematic LCD display. The twist angle of HTN-LCD is between 100 degrees and 120 degrees, which is between TN-LCD and STN-LCD. There are currently not many HTN-LCDs, and their performance is between TN-LCD and STN-LCD.

FSTN-LCD is the abbreviation of Film Super Twist Nematic Liquid Crystal Display. Here Film refers to the compensation film or retardation film, so FSTN-LCD is called the compensation film super twisted nematic LCD liquid crystal display. The shortcomings of STN-LCD can be overcome through a layer of specially treated compensation film.

TFT-LCD is an active matrix LCD of thin film transistors, which is currently the highest-grade product in the LCD market. It is mainly used in notebook computers, LCD color TVs, etc. The manufacturing process of TFT-LCD is relatively complex and the price is relatively high.

There are many types of LCD displays, which can be divided into transmissive and reflective direct-view displays according to the display mode.

The back of the transmissive LCD is equipped with light sources such as fluorescent lamps and electroluminescent electrodes. Therefore, it can also be used in dim ambient light.

The reflective type is a kind of aluminum foil light reflective sheet attached to the outside of the glass substrate on the back of the LCD to reflect the incident light of the LCD for display.

In TN and STN modes, back glass. The substrate is attached with a polarizer and a reflective sheet with wrinkles on the surface. This reflective type takes full advantage of the low power consumption of non-luminous LCDs.

The difference between lcd screen and led screen

There are significant differences between LCD screens and LED screens in many aspects.

First of all, from the perspective of driving method and working principle, LCD liquid crystal display panels usually require an external power supply to work. The working principle is to flow current through the electrodes on the glass substrate to the liquid crystal molecules to produce pictures. The LED screen does not require an external power supply. Its working principle is to directly convert electrical energy into light energy and then send out picture signals through the pixels.

Secondly, in terms of display effect, the LCD screen has a backlight layer that emits light by refracting light. The color saturation is relatively low, but the display effect is relatively natural, and it is not easy to fatigue after long-term viewing. The LED screen can self-illuminate, and each pixel can project light of the three primary colors of red, green and blue, so the display effect is more vivid and full.

In addition, the two also differ in thickness, power consumption, and screen life. The thickness of the LCD screen is relatively large due to the presence of a backlight layer and a liquid crystal layer. LED screens are relatively thin and light, making it easy to make mobile phones thinner. In terms of power consumption, when the LCD screen is turned on, the entire backlight layer is turned on. It can only be fully on or fully off, and the power consumption is relatively high. Each pixel of the LED screen works independently and can light up certain pixels individually, so the power consumption is lower. As for screen life, the LCD screen uses inorganic materials, which ages slowly and has a long life. LED screens use organic materials and have a relatively short lifespan.

Finally, from the perspective of application scenarios, LCD screens are widely used in traditional computer monitors, TVs and other fields due to their power saving, thin body, low radiation, soft picture and other characteristics. LED screens, with their high brightness, high definition, and long life, are widely used in billboards, outdoor displays, large-scale sports events and other field.

seolounge

seolounge